The day began early… again… this traveling is hard on a feline who gets cranky when he doesn’t get his 18 hours…. But The Lady was up and early and looking forward to tour BelGioioso, the home of Burrata, one of cheese god’s gifts to the devout cheeseheads of the world… and where I came from, as well…

BTW, I have been catching a few zees on the bus where I am often left in charge while the group is off doing their thing…

Today’s tour was at the Glenmore Plant where fresh mozzarella, including Burrata, and provolone were being made. Because they both are Pasta Filata style cheeses, their productions are compatible.

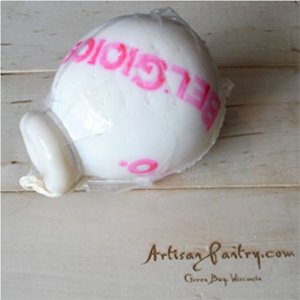

The plant was making Burrata and according to Dave Peterson, VP National Retail Sales, getting to see Burrata actually being made is quite a treat. The centers of the balls of fresh mozzarella are injected with the mixture of sweet cream and shredded mozzarella – all done by hand. Burrata is a special order item as it is a bit pricey with a short shelf life… oh, but worth every penny…

A more detailed explanation of the making of mozzarella and provolone will be in a follow-up post after The Lady and I return to the Pacific Northwest.

Bit of trivia: Mozzarella packed in water has a shelf life of 37 days while the cryovac version has a shelf life of 60 days. BelGioioso is now cryovaccing their fresh mozzarella pearls, which are perfect for Marguerite Pizza, salads and snacks.

The plant makes mild to sharp provolone; the intensity of this cheese being determined by the length of time the cheese stays in the brine… the sharpest being brined for 47 days before being sent to the aging room.

Dave explained that the salt in the brine is recycled through an osmosis system that allows the re-use of the water and the salt. He claims… and I believe him… that some of the salt in the plant is 15 years old… now that’s an old salt…

This plant makes mascarpone and ricotta; but production of these items had ceased for the day.

The mozzarella uses microbial (vegetarian-suitable) rennet while the provolone uses animal rennet.

One million pounds of milk comes into this plant daily and about 100K pounds of cheese is made. The ratio is between 10 and 13 pounds of milk for every pound of cheese produced. The rest is water and whey which are both used. The water is cleaned and recycled; the whey is used in making the mascarpone and animal feed. Little waste is a motto at BelGioioso which is indeed a green cheese company… not to be confused with green ham…

Provolone can be shaped into many forms; the most popular being the long salamis which can weight from 20 to 200 pounds each. They make mandolin shaped and also Manteche which is filled with butter. Back in the day, the butter was stored in the Manteche for preservation reasons. BelGioioso continues the tradition today.

After the tour, the group was treated to a cheese tasting of several of the fine BelGioioso line of 37 different cheeses hosted by Francis Wall. The tasting included Whole Milk Ricotta, Fresh Mozzarella, Crescenza-Stracchino (The Lady voted this as her favorite of the tasting – Burrata wasn’t on the plate…), both mild and sharp provolone, Parmesan, which won Best Parm in the world at the 2009 World Cheese Awards, Aged Asiago, Italico and Creamy Gorgonzola, which has a washed rind. They also treated the group to their new Roll and Wrap Mozzarella with Prosciutto and fresh, local basil.

Trivia: BelGioioso wraps their Gorgonzola in foil and then in cellophane with tiny holes so that the cheese can continue to breathe. Cryovac wrap causes the cheese to become wet; the holes in the cellophane prevent that, making for a better product.

Dave and Francis sent the group off with a cheese cooler and wedges of the aged Asiago and sharp Provolone.

The chesses from the tasting will be reviewed in further detail upon our return to the manse.

3 thoughts on “Wisconsin Cheese Tour – Day 3 – BelGioioso”

Comments are closed.

Hey, I found this post because I was trying to find out more about BelGioioso’s production processes. What I really want to know and didn’t find out from their website is, do they buy milk from confined cows or free-range pastured cows? Did you find that out in your tour? I would ask somebody at BelGioioso but their website offers no contact information!

From your website I do see the answer to one question I had, which is that apparently none of their cheeses are made from raw milk. Oh, well, if the cows are free-range I can live with it.

Thanks

Thanks for the comment. BelGioioso is a member of the Wisconsin Milk Marketing Board and as a member they agree to certain guidelines. One has to do with pasturing animals and a certain percentage of feeding must be grazing. BG buys its milk from hundreds of farmers who adhere to the rules and philosophies of the WMMB therefore, the milk comes from cows that are pastured under the guidelines of the WMMB.

I looked for these guidelines online and couldn’t find anything specific – can you point me to the actual guidelines? What is the percentage of pasture that is required? Are cows confined and fed grain the rest of the time? The WMMB website is all about marketing their cheese but not much about the milk. I’d love to find out that all Wisconsin cheeses are produced from cows that are primarily pasture-fed! It would make buying cheese so much easier!